Transforming Cold Chain Management for Efficiency and Sustainability

Introduction

Cold chain systems play a vital role in preserving the quality and safety of temperature-sensitive products, from food and beverages to pharmaceuticals and vaccines. However, traditional cold chain management faces challenges like inefficiencies, high energy consumption and product spoilage. With advancements in technology, the cold chain is evolving to ensure efficiency, reduce waste and promote sustainability, enabling businesses to meet growing demands while safeguarding the environment.

The Challenges of Traditional Cold Chains

- Temperature Fluctuations: Inconsistent temperature monitoring can lead to spoilage and compromised product quality.

- Energy Inefficiency: Cold storage facilities and transportation systems consume significant energy, increasing operational costs and carbon emissions.

- Limited Real-Time Visibility: The Lack of real-time data makes it difficult to identify and address issues promptly.

- Product Losses: Inadequate cold chain integrity results in financial and reputational losses.

Emerging Innovations in Cold Chain Management

The integration of advanced technologies is transforming cold chain operations, ensuring better efficiency, quality control and sustainability.

Real-Time Monitoring

- IoT sensors provide continuous tracking of temperature and humidity, ensuring compliance with storage requirements.

- Instant alerts for deviations enable quick action to prevent spoilage.

Predictive Analytics

- Machine learning algorithms predict equipment failures, allowing for proactive maintenance.

- This minimizes downtime and reduces the risk of disruptions.

Energy Optimization

- Automated energy management systems regulate refrigeration units, optimizing energy usage while maintaining required conditions.

- Solar and renewable energy integration is becoming a popular option for greener operations.

End-to-End Visibility

- GPS and cloud-based systems offer complete transparency into the cold chain, from warehouses to delivery points.

- Businesses can track product conditions in transit, ensuring consistent quality.

Benefits of Advanced Cold Chain Solutions

- Enhanced Product Quality: Products are stored and transported under optimal conditions, ensuring freshness and safety.

- Reduced Wastage: Real-time monitoring and predictive systems minimize spoilage and product loss.

- Cost Savings: Optimized energy consumption and proactive maintenance lower operational expenses.

- Sustainability: Improved energy efficiency and reduced waste contribute to a greener supply chain.

Real-World Applications of Smart Cold Chains

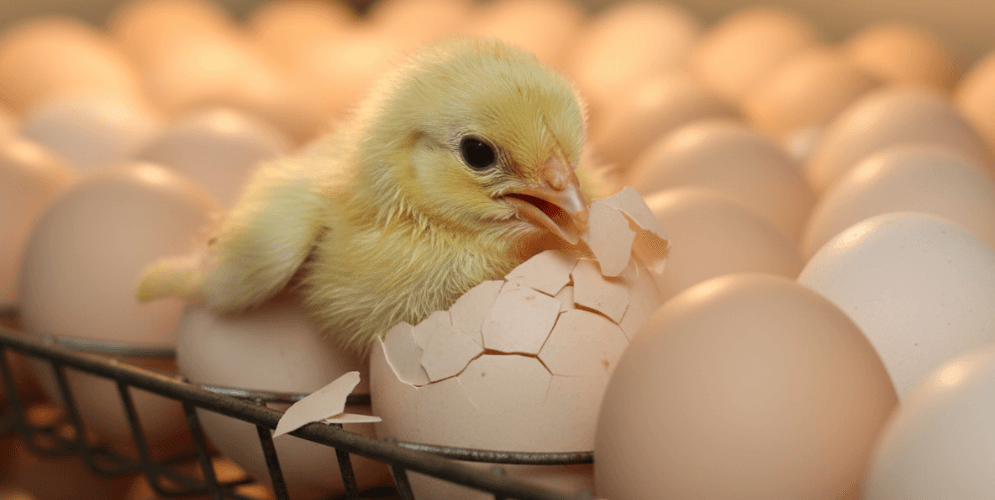

- Food Industry: Precision temperature control prevents spoilage during storage and transportation of perishable items like dairy, meat and seafood.

- Pharmaceuticals: Vaccine safety is ensured with continuous monitoring of cold storage facilities and delivery vehicles.

- Agriculture: Fresh produce is preserved for extended periods through controlled environments, reducing food waste.

Sustainability in Cold Chain Management

Cold chains are increasingly adopting sustainable practices to align with global environmental goals. These include:

- Using energy-efficient cooling systems and renewable energy sources.

- Reducing single-use packaging by adopting reusable alternatives.

- Implementing data-driven systems to optimize transportation routes, reducing fuel consumption.

Conclusion

Modern cold chain management is not just about maintaining temperatures; it's about achieving a balance between operational efficiency and environmental responsibility. By adopting innovative solutions, businesses can ensure product integrity, reduce waste and contribute to a more sustainable future.

Keep Exploring Our Blog Collection