Revolutionizing Steam Systems: Optimizing Performance with Advanced Vibration and Thermal Sensing to Maximize Energy Efficiency

Boiler Industries

UN SDG 9 - Industry, Innovation and Infrastructure

Chennai

Pain Points

The customer faced inefficiencies in their steam systems, resulting in excessive energy consumption and maintenance costs.

Inefficient Steam Trap Performance

Steam traps were malfunctioning, causing energy loss due to blocked or leaking traps, reducing system efficiency.

Lack of Real-Time Monitoring

Lack of Real-Time Monitoring

High Maintenance Costs

Unpredictable steam trap failures resulted in high maintenance costs due to reactive repairs.

Our Offerings

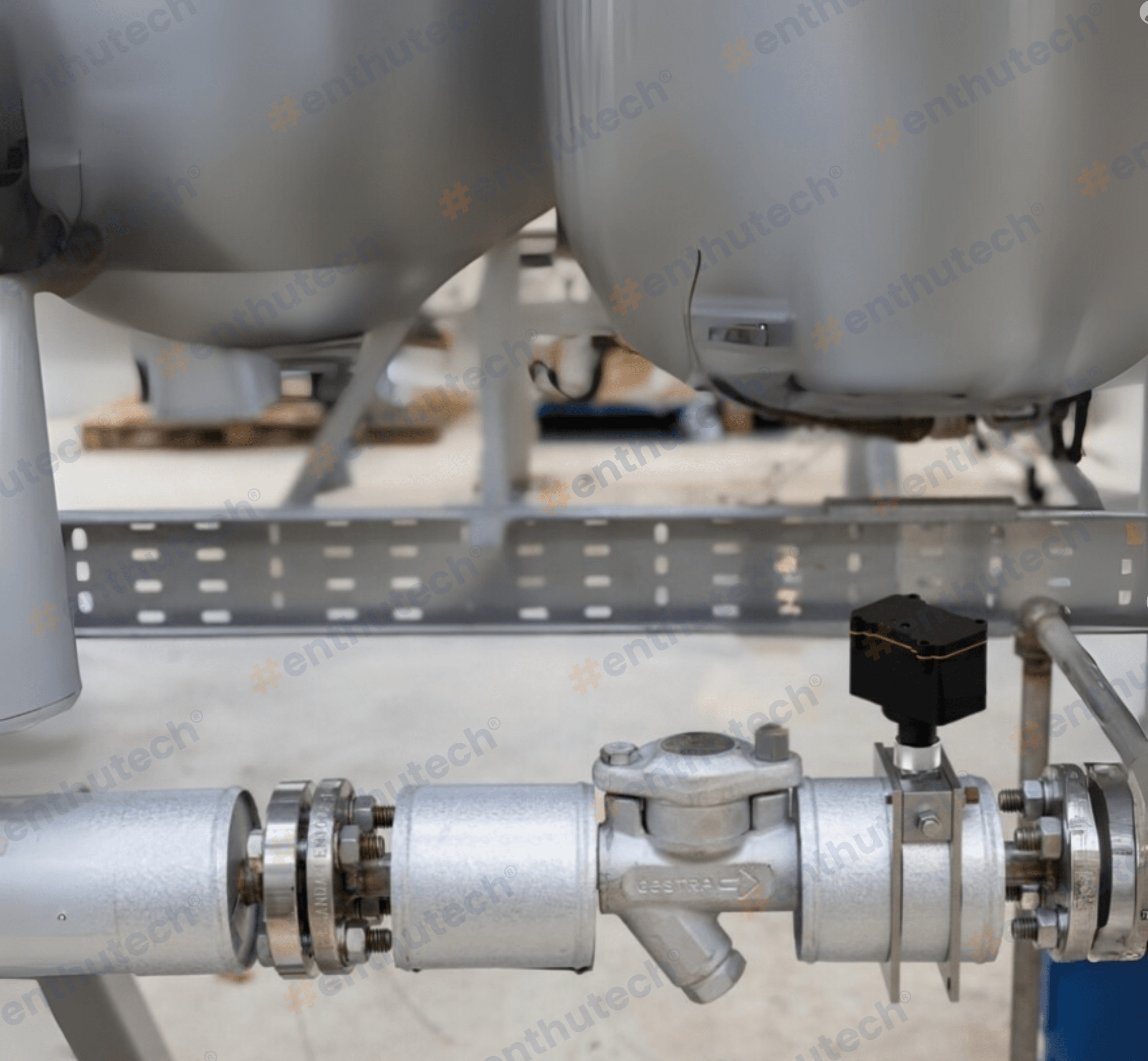

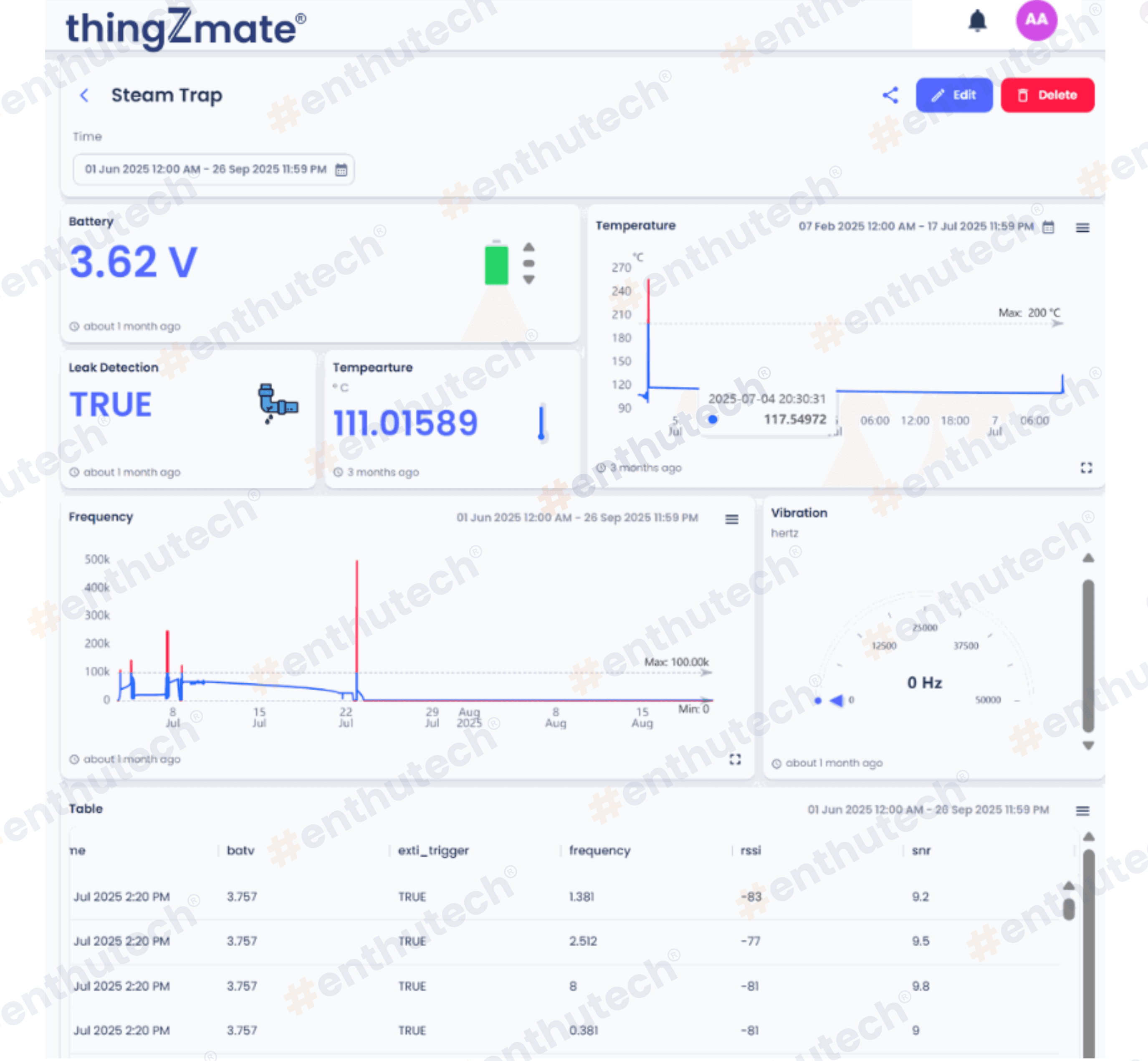

We provided an IoT-based solution that enabled real-time monitoring of steam trap performance, improving efficiency and reducing maintenance costs.

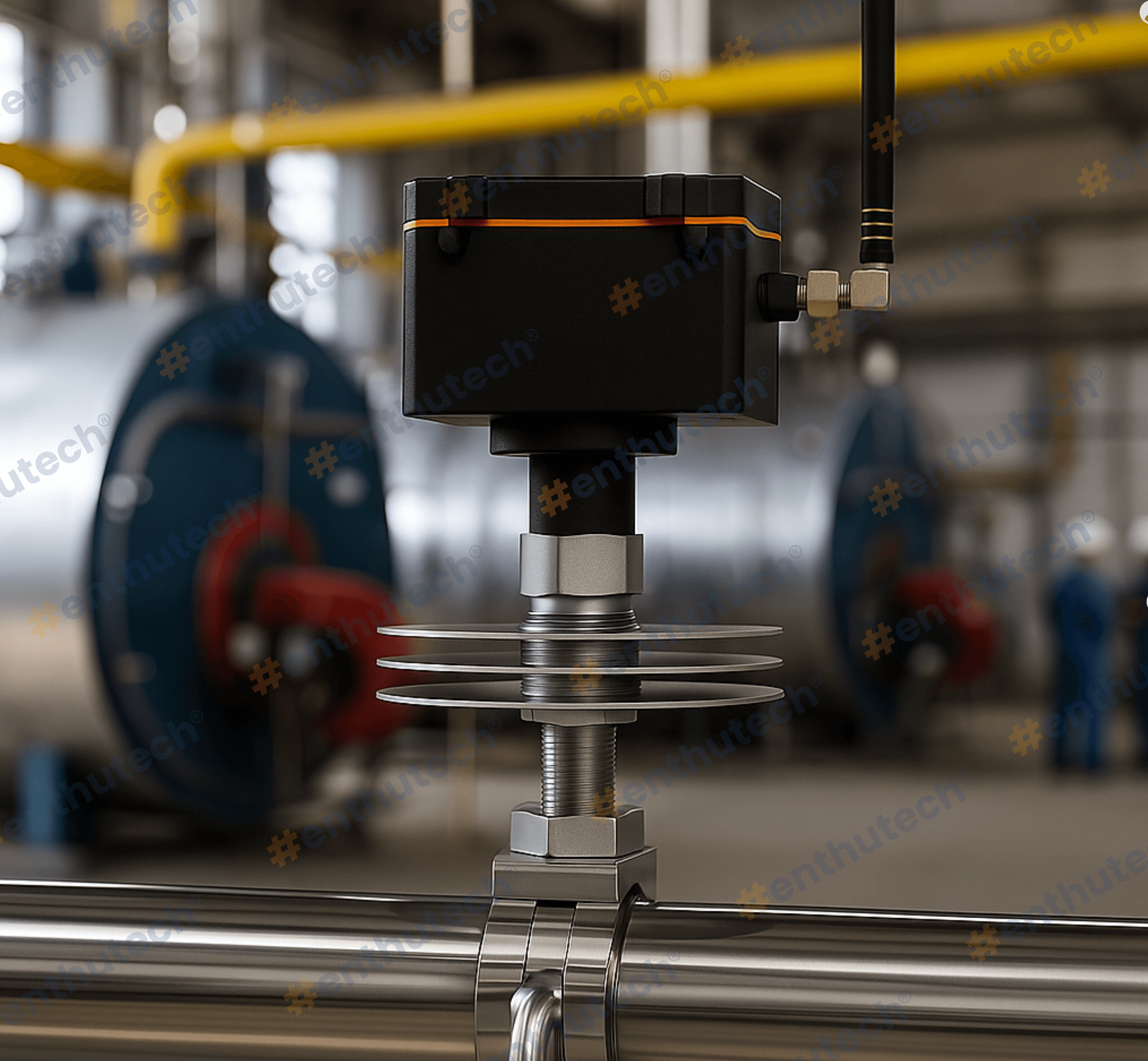

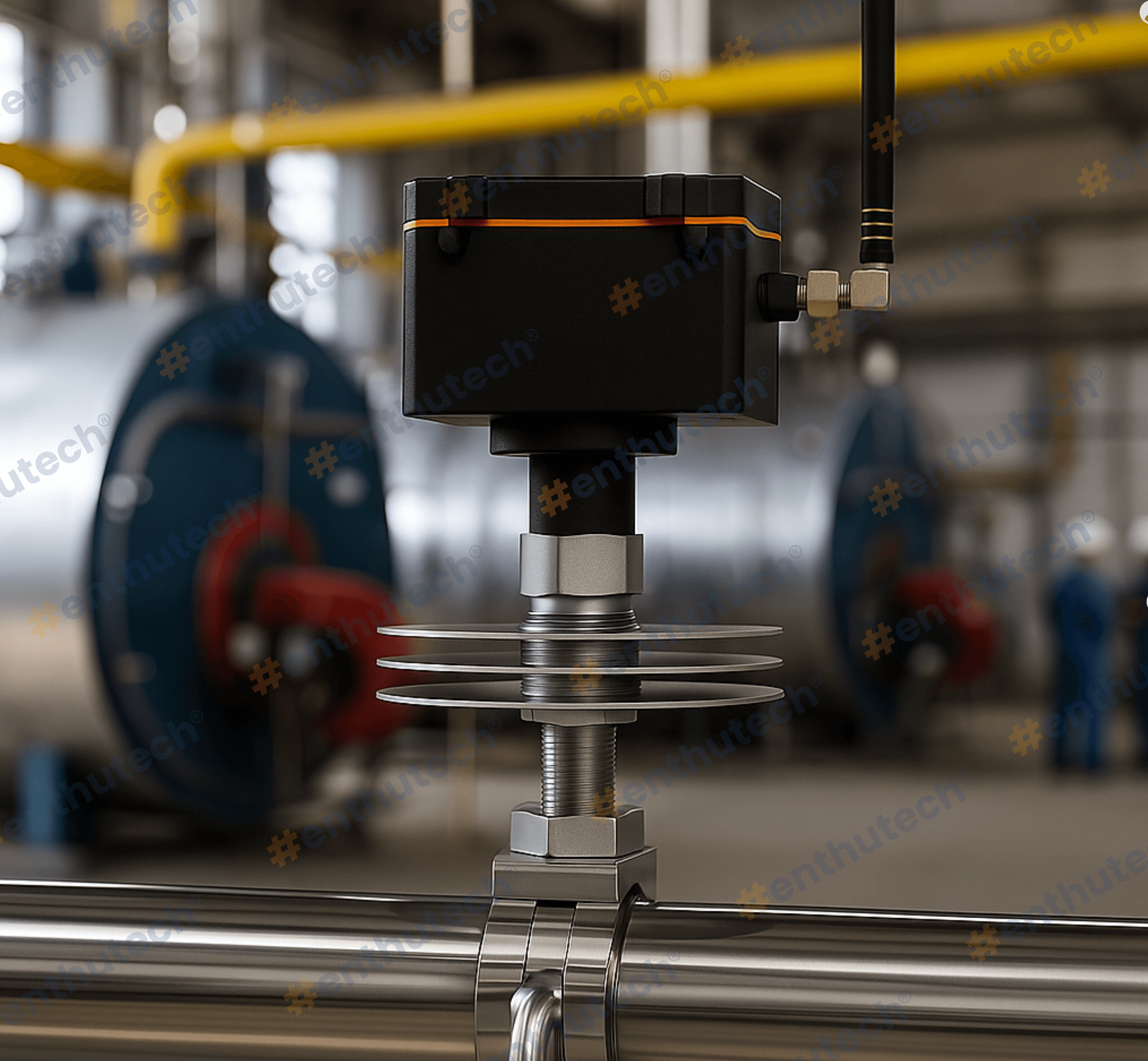

Vibration and Temperature Sensing

Deployed advanced vibration and temperature sensors to monitor steam trap performance, detecting anomalies in real time.

Predictive Maintenance System

Integrated predictive maintenance algorithms to forecast potential failures and schedule proactive maintenance.

Centralized IoT Control

Implemented a centralized IoT controller to aggregate sensor data and trigger alerts for anomalies, enabling quick interventions.

Energy Optimization

Optimized steam system efficiency by ensuring only fully functional traps were in operation, leading to energy savings.

Outcomes

Energy Savings

Reduced energy consumption by 15% by ensuring steam traps operate optimally and prevent steam leaks.

Reduced Downtime

Achieved a 30% reduction in unplanned downtime through early failure detection and predictive maintenance.

Lower Maintenance Costs

Maintenance costs were reduced by 20% by shifting to a proactive maintenance strategy.

Improved Operational Efficiency

Optimized steam trap performance resulted in improved overall system efficiency, enhancing production capacity.

Real-time monitoring has transformed our steam system, boosting energy efficiency and cutting downtime.

Real-time monitoring has transformed our steam system, boosting energy efficiency and cutting downtime.

Get in Touch

© 2025, Enthu Technology Solutions India Pvt. Ltd. All Rights Reserved.