Smart Poultry Chiller Health Monitoring: Real-Time Temperature and Humidity Insights for Efficient Cold Chain Management

Swamy Feeds Pvt Ltd

UN SDG 12 - Responsible Consumption and Production

Soolagiri - TN

Pain Points

Manual chiller checks led to temperature deviations, product loss, and poor efficiency.

Unstable Chiller Temperature

Frequent fluctuations in temperature affected poultry freshness and storage life.

Manual Monitoring Delays

Operators relied on periodic manual readings, missing real-time condition changes.

High Energy and Maintenance Cost

Lack of automated alerts caused prolonged chiller run times and maintenance issues.

Our Offerings

Below are the details we offer to address the above challenges,

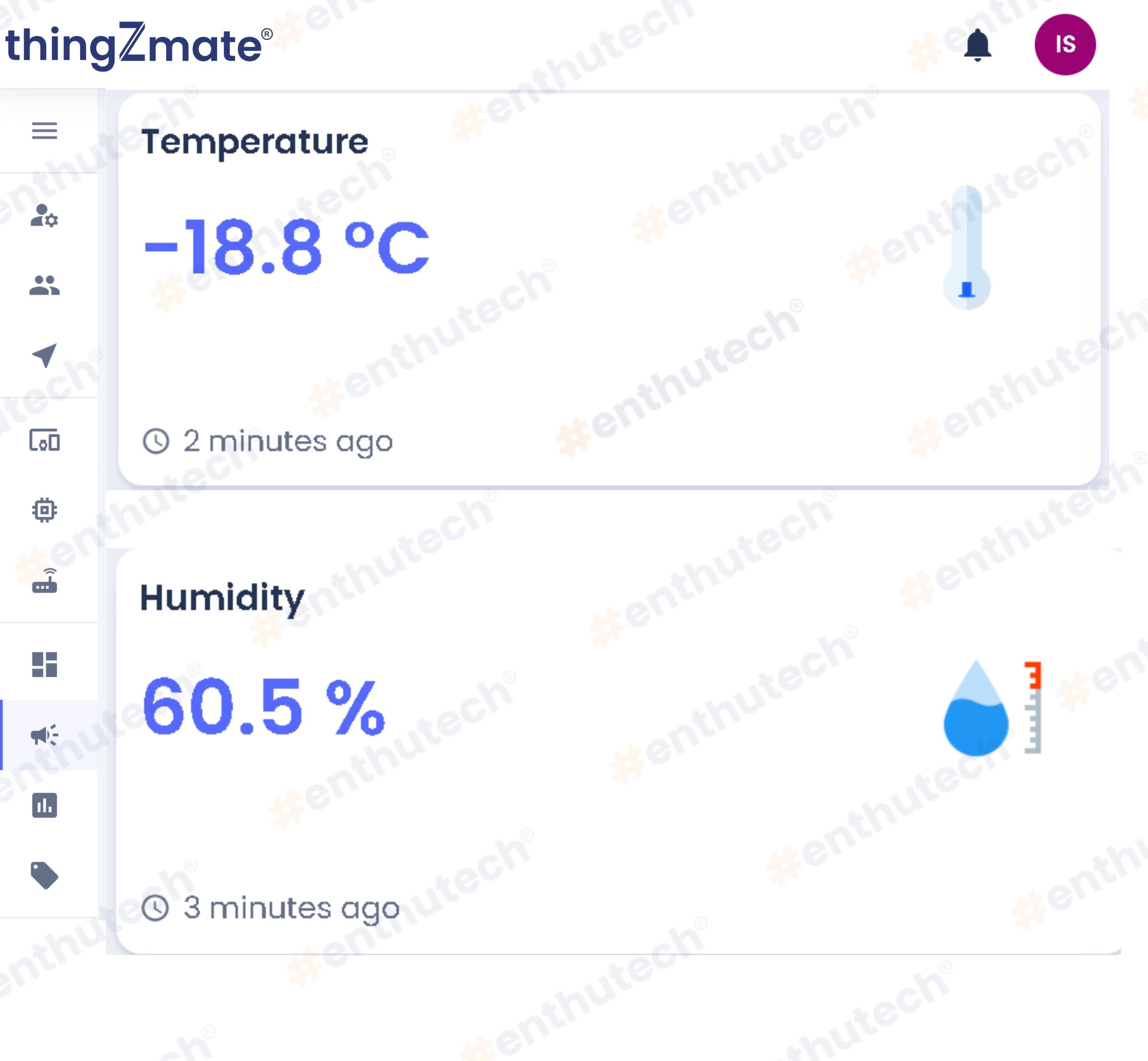

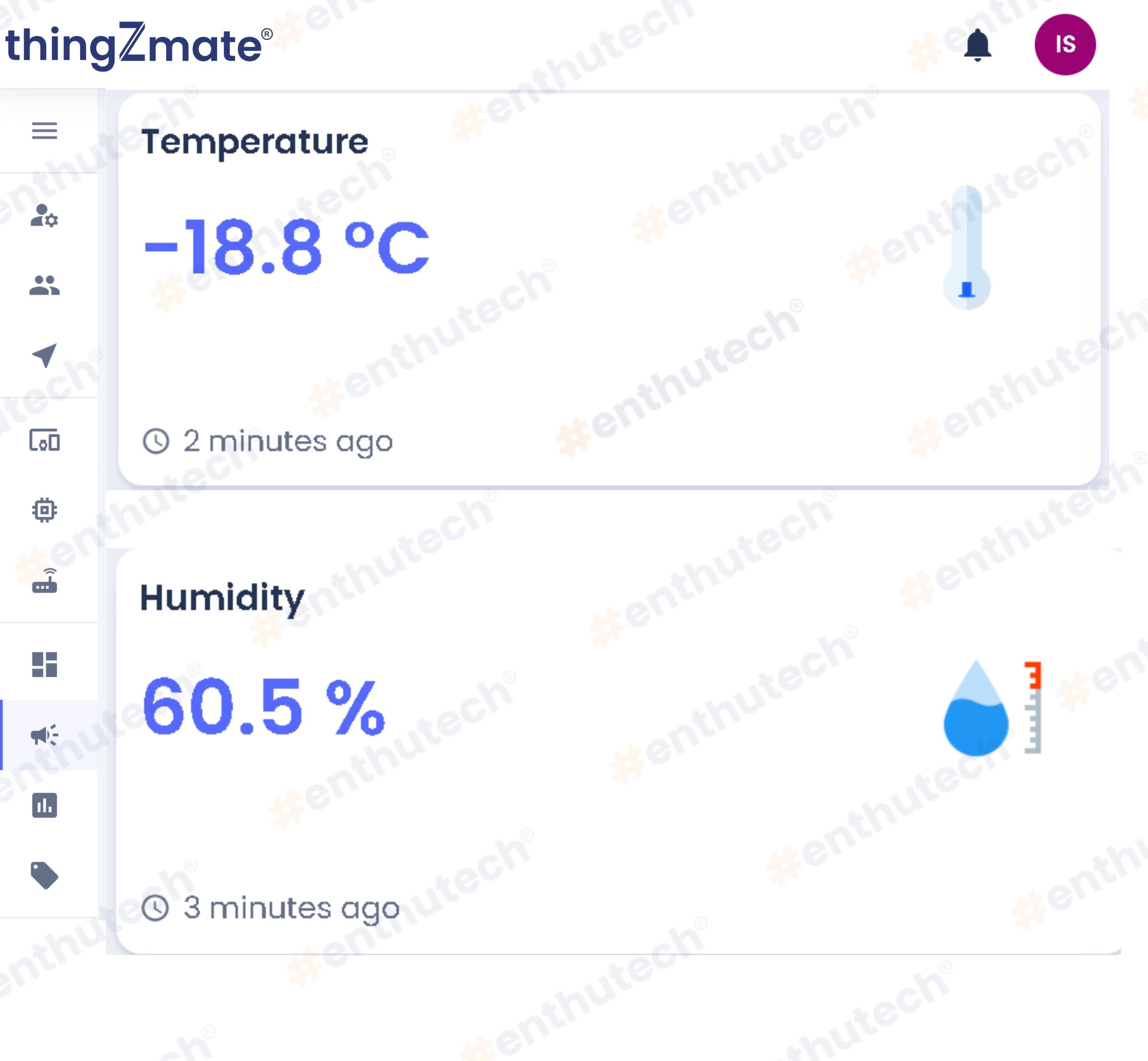

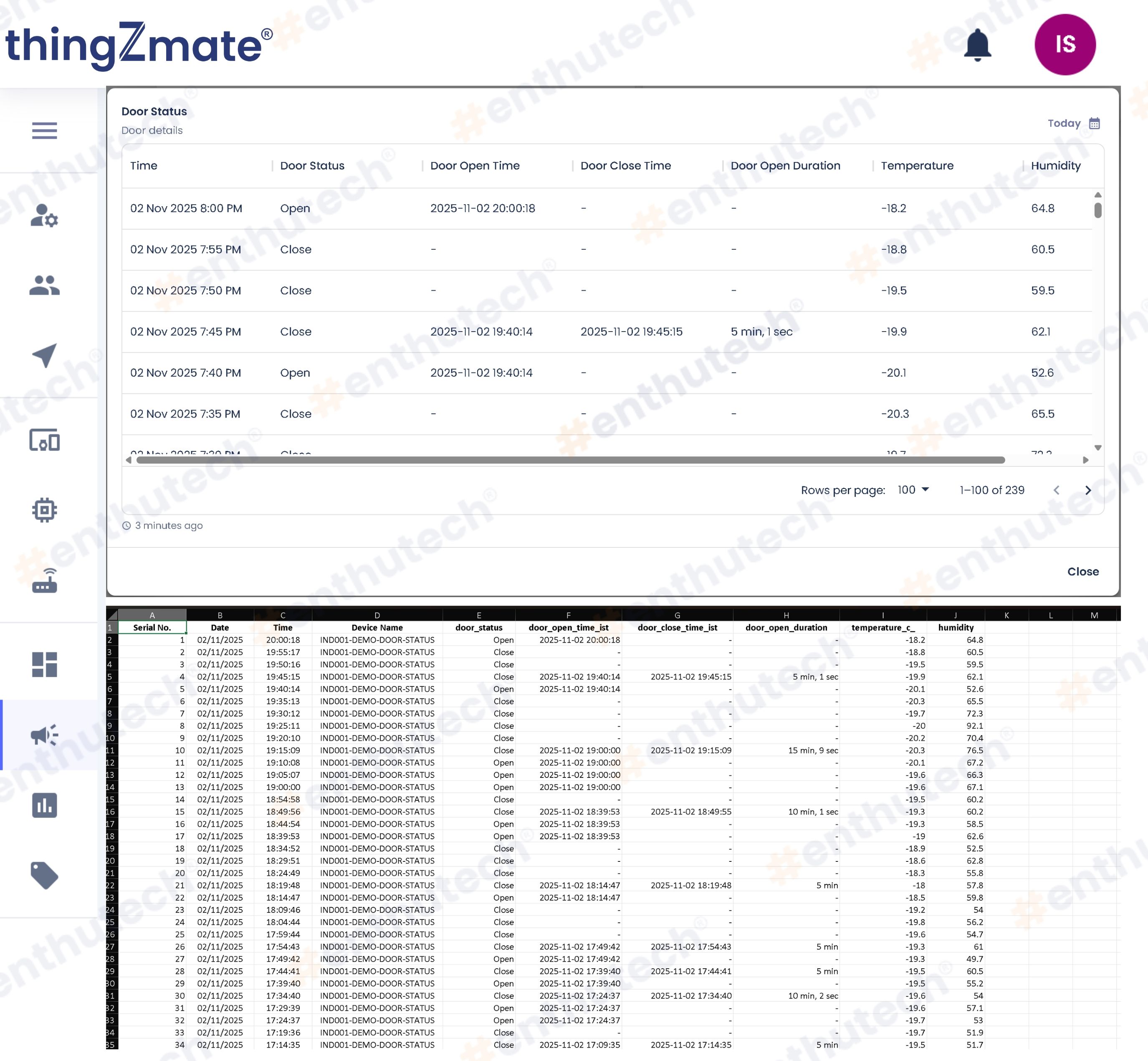

Real-Time Temperature Monitoring

Continuously tracks chiller temperature to ensure optimal cold storage performance.

Humidity Monitoring

Monitors internal humidity levels to prevent condensation and product degradation.

Cloud-Based Alerts

Instant notifications for any deviation in temperature or humidity thresholds.

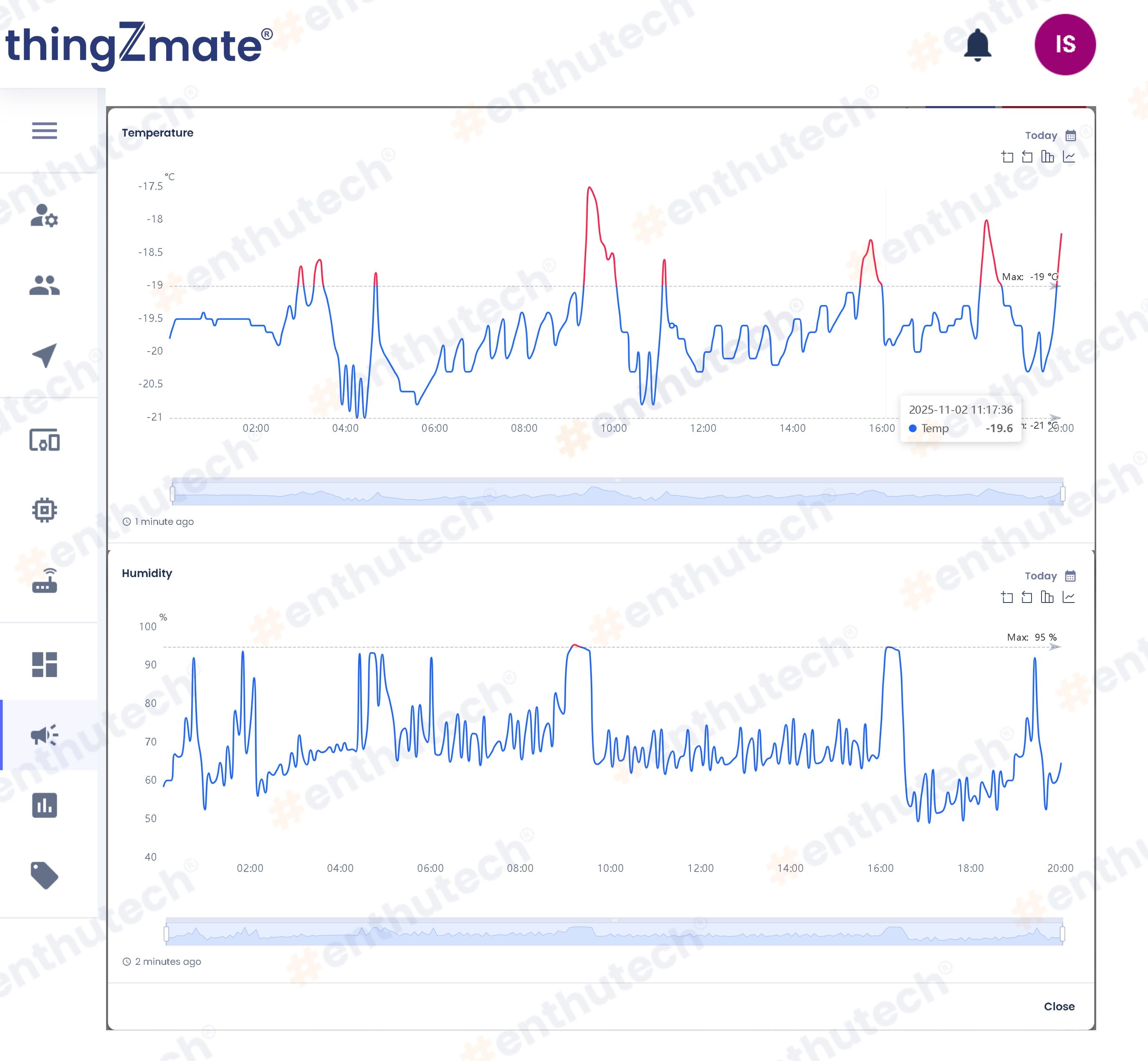

Data Logging & Analytics

Cloud dashboard stores data for performance analysis and preventive maintenance.

Outcomes

Reduced Product Spoilage

Maintained optimal chiller conditions improved poultry shelf life and quality.

Energy Optimization

Timely alerts reduced energy wastage and improved chiller operational efficiency.

Improved Cold Chain Reliability

Continuous monitoring ensured temperature stability throughout cold storage.

Data-Driven Maintenance

Historical analytics supported predictive maintenance and reduced downtime.

![]() Our chiller monitoring system helped maintain perfect storage conditions and reduced losses.

Our chiller monitoring system helped maintain perfect storage conditions and reduced losses.

Get in Touch

© 2025, Enthu Technology Solutions India Pvt. Ltd. All Rights Reserved.